Stix - Long Seam Weld Scanner

Overview

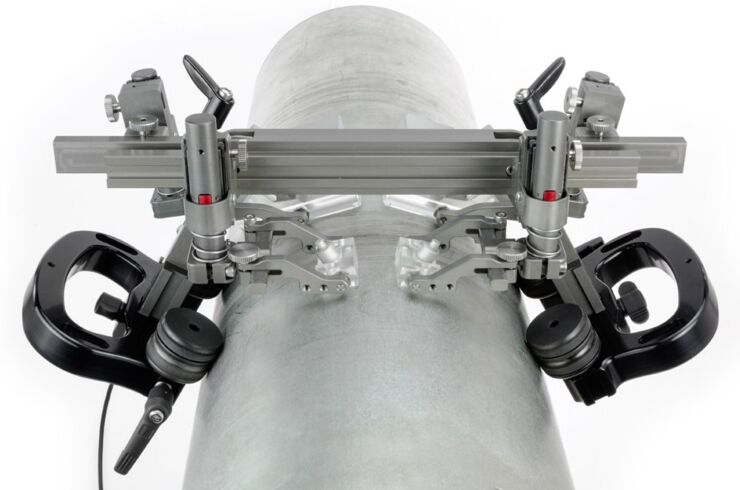

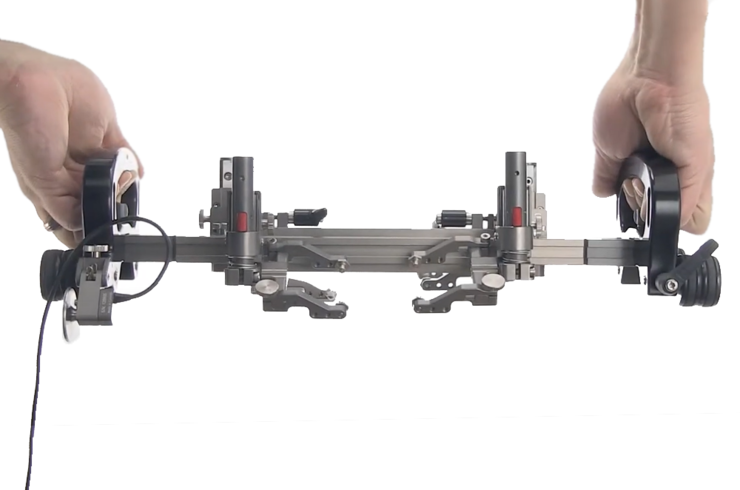

The STIX - Long Seam WELD scanner is specially designed to translate Phased Array and/or TOFD probes along both sides of a pipe longitudinal seam weld. Available in two versions, this magnetic scanner can handle 2 or 4 probe wedges for longitudinal scanning down to a 150 mm (6 in) pipe diameter. It can also handle flat surface inspection as well as circumferential scanning down to 275 mm (10 in) pipe diameter.

Features

-

Using two link lengths and an adjustable buckle, any size of pipe can be inspected from 152.4 mm - 965.2 mm (6 in - 38 in) diameter. Links are designed with quick releases to easily be added or removed.

- A double wheel chain is used to straddle the weld. This allows the scanner frame to be centred on the weld to reduce wandering and reduce the width of the scanner.

- An integrated latch allows easy probe centre spacing adjustment and scanner installation. Due to its modular design most major types of phased array wedges can be accommodated.

- All wheels are coated with urethane to reduce the effects of foreign debris obstructing the rolling of the scanner. Urethane also eliminates the sideways sliding of the scanner when used in vertical applications.

- A brake is provided to lock the location of the scanner in a required position.

- The encoder output is fully compatible with all standard instruments.

- The scanner is sealed using O-ring gaskets and seals to protect against penetration of contaminants into the unit.

| Part Number |

Description |

|---|---|

| JX-KIT-2-LONGSEAM | Long Seam Weld Scanner 2 probe holders |

| JX-KIT-4-LONGSEAM | Long Seam Weld Scanner 4 probe holders |

Specifications:

- Pipe Range, Circumferential: 25.4 cm (10 in) to flat

- Pipe Range, Longitudinal: 15.2 cm (6 in) to flat

- Encoder Resolution: 9.05 counts/mm (230.0 counts/inch)

- Probe Holding Capacity: 2 phased array wedges

- Encoder Cable Length: 5 m (16.4 ft)2

- Inspection Surface: Ferrous materials

What's in the box?

- STIX long seam frame with 8 magnetic wheels

- Spring-loaded encoder

- Vertical phased array probe holder x2

- Vertical TOFD probe holder x2

- Probe holder arm set – long, drop arm x2

- 4 mm ID irrigation kit (7/16 in Quick Connect)

- Probe holder spare parts kit

Resources

Phased Array Technique for Inspection of Contact Point Corrosion

The PA-CAT™ phased array technique developed by Holloway NDT & Engineering Inc. is an attenuation-based modelling algorithm used to evaluate the minimum remaining wall thickness at pipe or vessel supports.

Austenitic Stainless Steel Solution DAAH – Dual Linear Array Probe

300 series stainless steels are the most common sub-group of austenitic steels and are used in a large variety of processes and industries, typically for corrosion resistance of high temperature service. Comprehensive inspection techniques are vital to ensure safe operation.

Long Seam Weld Inspection – Manual

This package is specifically created for a quick and easy solution to manually inspect Long Seam Welds.

Long Seam Weld Inspection – Encoded (Semi-Automatic)

The tools in this package are specifically selected to provide an easy and accurate solution for the semi-automatic encoded inspection of long seam welds.

Dual Linear Array (DLA) – Encoded Weld Inspection

Dual Linear Array probes provide an adaptive and modular solution for weld inspection of material with high signal attenuation as they can significantly improve signal to noise ratio.

Curved Surface Correction (CSC) for Long Seam Weld Inspection

Phased Array inspection of curved components can be challenging, especially for seam welds in small diameter or heavy wall pipes as inspection software tools and accessories are generally designed for flat surfaces.