Marine

Alternative composite materials avoid corrosion but bring different inspection challenges.

Operating in harsh saline environments marine vessels are subject to corrosion and hence the need for inspection, quickly over large surface areas. Our non-destructive testing will give you an understanding of how your material is ageing in a marine environment.

Marine Resources

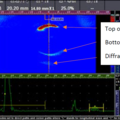

Low Frequency GFRP Imaging with Variable Aperture TFM

Technical Papers

Composite Inspection Benefits and Challenges Using Ultrasonic NDT Solutions

Ultrasonic Non-Destructive Testing (NDT) is widely used by engineers to inspect a range of composite materials including aluminium laminates and…

Technical Papers

TFMi™ Inspection for monitoring "Blind" Holes

Blind hole inspection is an excellent fit for TFMi™. It really enables a full comprehensive profile view of the internal geometry of a part.

Application Notes

Echo to Echo and Coating Thickness Measurements

Many applications in the Corrosion thickness applications have painted surfaces on vessels, ship hulls, pipes, bridges, and tanks.

Application Notes

Marine Products

Prisma

The prisma ultrasonic flaw detector offers the end user, outstanding performance in the field together with the flexibility and capability to step up…

Sitescan 500s

Sonatest Sitescan Flaw Detectors have always meant highly reliable, technician focused and this range continues this tradition.

Sitescan D-50

Sonatest Sitescan Flaw Detectors have always meant highly reliable, technician focused flaw detection equipment and this model builds on that…

Masterscan 700m

The Masterscan name has always assured the technician of robust instrument construction combined with exceptional performance.

Masterscan D-70

The Masterscan name has always assured the technician of robust instrument construction combined with exceptional performance.

Features can be added…