Aerospace

Safety is paramount in Aerospace. Fast extensive inspection is now possible using the improved ultrasonic wheel probes.

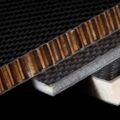

The use of novel composite materials and non-destructive testing equipment presents: test and inspection challenges which Sonatest have resolved.

Aerospace Resources

Ultrasonic Inspection Methods for Composites in Motosports

Composites have become a dominant material in motorsport, accounting for up to 85% of the vehicles used today. This includes all levels of Formula…

Solutions

Low Frequency GFRP Imaging with Variable Aperture TFM

Technical Papers

Composite Inspection Benefits and Challenges Using Ultrasonic NDT Solutions

Ultrasonic Non-Destructive Testing (NDT) is widely used by engineers to inspect a range of composite materials including aluminium laminates and…

Technical Papers

Advanced Composite Inspection

A complete picture of a large component can be produced by stitching C-scans together in the UTmap software.

Solutions

Aerospace Products

RSflite Composite Solution

Portable Ultrasonic NDT Solution for the Composite Industry.

Single Element WheelProbe

The Single Element WheelProbe uses Sonatest rubber technology for near-dry ultrasonic coupling.

WheelProbe 2

The WheelProbe 2 has demonstrated unparalleled performance in the realm of composite inspection and corrosion monitoring, excelling in terms of both…

Prisma

The prisma ultrasonic flaw detector offers the end user, outstanding performance in the field together with the flexibility and capability to step up…

Sitescan 500s

Sonatest Sitescan Flaw Detectors have always meant highly reliable, technician focused and this range continues this tradition.