Educational Notes

Ultrasonic Inspection of Welds e-Book

26th August 2021

Download our latest eBook covering ultrasonic weld inspection, one of the key applications of non-destructive inspection.

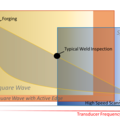

Ultrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY Joints

12th November 2020

This is the third and final in a series of notes related to weld inspection, one of the key applications of non-destructive inspection. This Education Note focusses on ultrasonic inspection of welds in nozzles, nodes, curved surfaces and TKY joints.

Ultrasonic Inspection of Welds in Tubes and Pipes

7th October 2020

This is the second in a series of notes related to weld inspection, one of the key applications of non-destructive inspection. This Education Note focusses on ultrasonic inspection of welds in tubes and pipes.

Ultrasonic Inspection of Welds in Flat Plate

6th October 2020

This is the first in a series of notes related to weld inspection, one of the key applications of non-destructive inspection. This Education Note focusses on ultrasonic inspection of welds in flat plate.

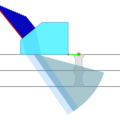

Different Types of Focusing

31st July 2020

Focusing is a phenomenon in which a maximum level of acoustic energy is concentrated at a given point. There are various types of focusing methods - constant path, constant depth, constant offset and natural.

What is Linear Scanning

23rd April 2020

Linear scanning is generally recognised to be the best non-destructive testing (NDT) solution for the volumetric examination of many structures.

Dryscan or Shadow Technique

23rd April 2020

With the Dryscan technique, highly effective signal transmission can be achieved by using a completely dry contact system.

Types of UT Transducers (Pulsers)

23rd April 2020

There are two types of UT pulsers that are commonly used, the spike pulser and the square wave pulser; both have advantages and drawbacks.

Optimal Workflow for Composite Inspection

23rd April 2020

For ultrasonic linear scanning evaluation, a good workflow includes 3 simple steps.

Accurate Top Views using Extraction Boxes

21st April 2020

Using Sonatest’s unique extraction boxes, inspectors can directly extract the height and width of the flaw without any compromise.

How to Analyse C-scan Mapping?

21st April 2020

Ultrasonic flaw detectors record complete A-scan information and can use it to create a two-dimensional C-scan map.