Types of UT Transducers (Pulsers)

There are two types of UT pulsers that are commonly used, the spike pulser and the square wave pulser; both have advantages and drawbacks.

Ultrasonic (UT) inspection instruments create a pulse of ultrasound which is used to identify flaws when passed through a component.

A pulser in the instrument generates electrical excitation in a transducer to produce the ultrasound pulse. There are two types of UT pulsers that are commonly used, the spike pulser and the square wave pulser; both have advantages and drawbacks.

Spike Pulsers

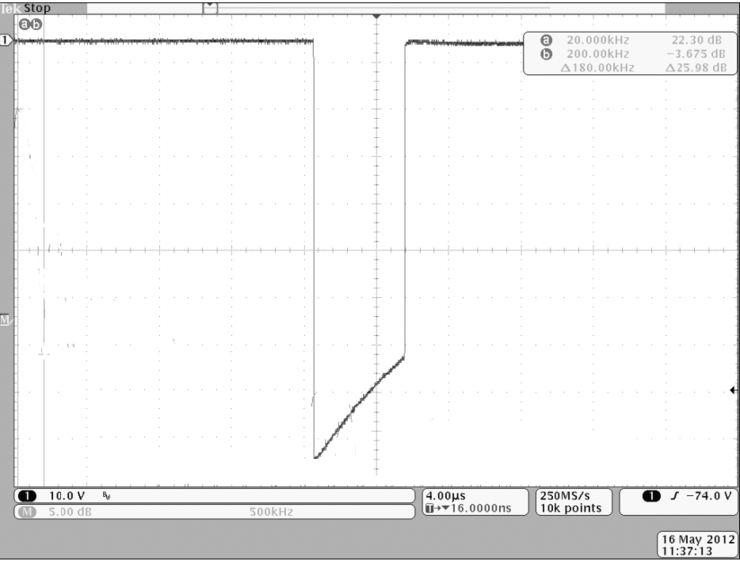

These were the first pulsers produced and have been available for many years. They are simpler to design and integrate into instruments. Providing very fast rise times and very short durations (hence the name “spike”), they are qualified as broadband. A broad spectral excitation allows them to work well with probes of all frequencies. Moreover, most of these pulsers have an adjustable maximum voltage and damping resistors which make it possible to modify the spike produced in order to better match them with some probes.

Spike pulsers are a good choice when inspecting thin materials, when high frequency transducers are used, and when fast recovery times and near-surface resolution are important.

|

|

|

|

Square Wave Pulsers

Square wave pulsers are not only tuneable in amplitude; they also have the capability of adjusting the duration of the pulse. This fine-tuning of the period enables the production of a signal with a base frequency that matches the natural or central frequency of the transducer.

Square wave pulsers provide much higher energy levels to the transducer, making them ideal for thick samples or highly attenuative materials. At the cost of higher power requirements and therefore reduced battery life, these pulsers bring much better penetration. However, a high voltage and a long pulse duration may cause premature aging of the probe (mostly ceramic transducers). Moreover, higher energy levels can produce signals of up to 15 dB higher when compared to spike pulsers; this results in significantly improved signal-to-noise ratios.

Damping resistors are frequently used with spike pulsers in order to fine-tune the rise time of the pulse and optimize the transducer’s response. This damping resistor is not required with a square wave pulser as it is possible to fine-tune the pulse period to adequately match the probe.

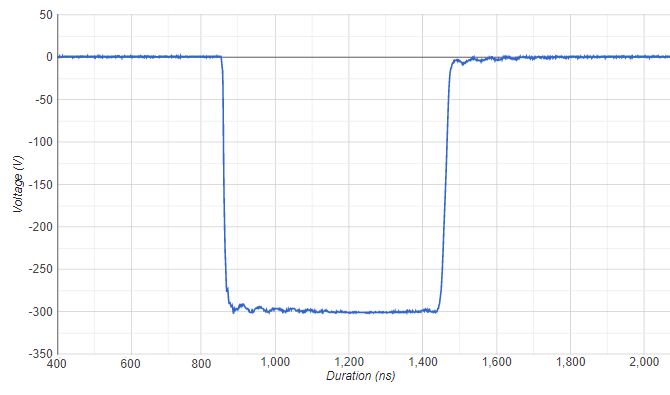

Several years ago, Sonatest developed Active Edge. This technology actively pulls the negative pulse back to zero much more rapidly, producing a very sharp edge at the end of the pulse. The pulse width can be adjusted very precisely and the rapid voltage transition helps improve near surface resolution. As it can be seen in Figure 2 below, the pulse is perfectly square despite having a high 300 volts amplitude and a long 600 ns duration. Active Edge is offered on all Sonatest products.

|

|

|

|

Typical Usage

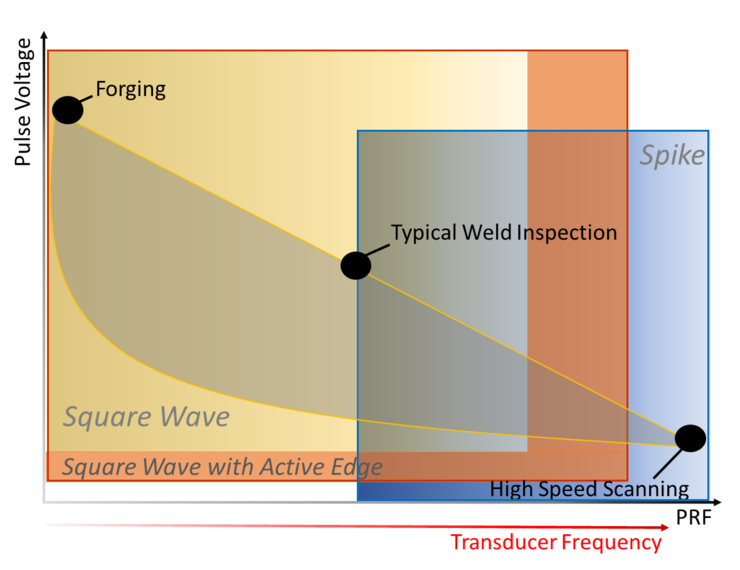

Figure 3 below shows when both spike and square wave pulsers are used and demonstrates

square wave pulsers are:

- particularly efficient for inspections like forging (or highly attenuative materials)

- frequently used at low frequencies and low PRFs (Pulse Repetition Frequency)

spike pulsers are:

- Frequently used for high-speed scanning, at high PRF’s and with higher frequency transducers

|

|

|

|

Also note that the grey shaded area below the straight line, crossing the figure, shows how both types of pulser are typically used in practice. That is, high-voltage pulses are mainly used at lower PRFs and with lower-frequency probes, as high frequency transducers are often used to perform scans at higher speeds that require higher PRF’s.

Finally, remember that the above figure does not mean forging applications cannot be performed using a spike pulser. Rather, it indicates that for this type of inspection, a square wave pulser is more appropriate and more commonly used.