WheelProbe 2

Overview

The WheelProbe 2 has demonstrated unparalleled performance in the realm of composite inspection and corrosion monitoring, excelling in terms of both speed and user-friendliness while consistently delivering outstanding results.

Coverage and precision are the keys to a successful mapping inspection. Our WheelProbes offer a 0.8 mm lateral resolution and now up to 100 mm coverage width. (0.031 inch pitch and 4.0 inches respectively in imperial system).

Applications where the WheelProbe 2 is currently in use include, aeronautical and astronomical aerospace part inspections, marine hull inspections, corrosion mapping asset integrity inspections in the oil and gas industry, composite inspections in the automotive and structural industries and many more.

You can indeed utilize our probe in those specific aerospace scenarios: stiffener bonding control or also during corrosion detection under wing spar cap.

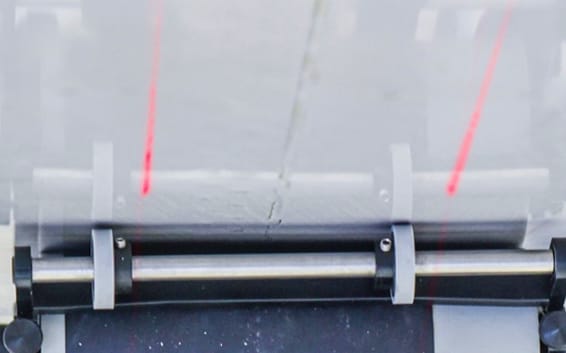

Figure 1 WP2 E128 with

Dual Integrated Laser

Composite Inspection

WP2 presents the most efficient solution for scanning large areas of composite. As the best alternative to immersion inspection, the WP2 offers an impressive 1mm near surface resolution in the latest composite materials using 5MHz array. Available also with 10 MHz and a 2.0 MHz version, the WP2 tyre tightly matches the acoustic impedance of water and like its predecessor, produces UT signals of exceptional quality. The configurable handles, adjustable laser guidance, unique LED's for alarm feedback, remote control with start/stop indexing and reset buttons as well as the remote display makes this package unique, superior and still unequalled.

Figure 2 Scrolling Thickness C-scan

Corrosion Monitoring

At Sonatest, we offer complete and reliable equipment to generate high quality corrosion map surveys. With the efficiency, performance and precision provided by the WP2, it is now possible to inspect larger area even faster and and provide high quality visual results immediatley in the live C-Scan (as seen in figure 2).

Large Area C-scan Evolution: An easy task to UTmap or UTstudio+

Moreover, this technique allows the user to compare large amounts of data over time to perform preventative maintenance, reducing potential downtown. The WheelProbe array provides high quality data that can efficiently analyse with our PC software or even third-party software such as CIVA Analysis.

WP2's is the tool of choice for a fast and accurate corrosion monitoring application!

Features

Light and Robust Design

You can trust it to perform the most rigourous inspection tasks, day after day.

Well Defined Laser Rolling

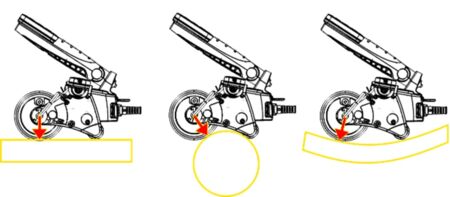

Figure 3 Wing spar inspection

Equipped with two LED feedback indicators (WP2 E128 features two lasers) and the optional display attachment, technicians can now prioritize the acquisition of consistently high-quality UT data. These dual guiding lines serve multiple purposes, including highlighting the anticipated C-scan zone or providing surface guidance along a designated surface geometry.

We can immediately see in figure 3 the benefit when the inspector checks the wing spar corrosion. The laser highlights the region of interest from beside of the rivet line.

Many Detachable Cable Options

Make the best use of your WP2, and connect it to just about any PAUT system. With interchangeable cables, you have the best of all worlds. A longer cable? A different connector? These options can be held in stock at very little cost, ready for the jobs as they arrive.

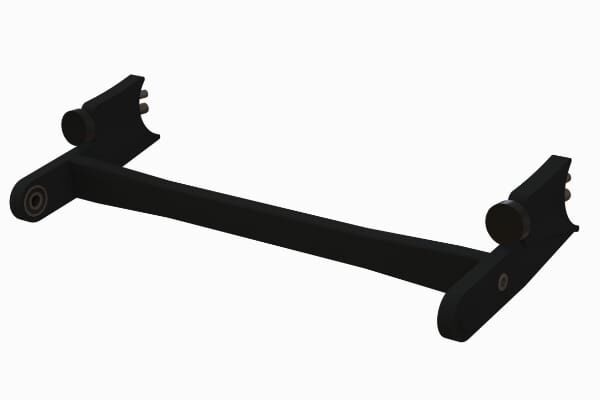

Configurable Handle

With a choice of either a single 'joy-stick' or a crossbar handle, the angle can be adjusted for operator comfort, and with the remote control available for either left or right-handed operation, the ergonomics of this WP2 are unsurpassed.

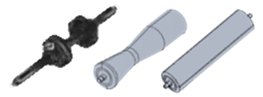

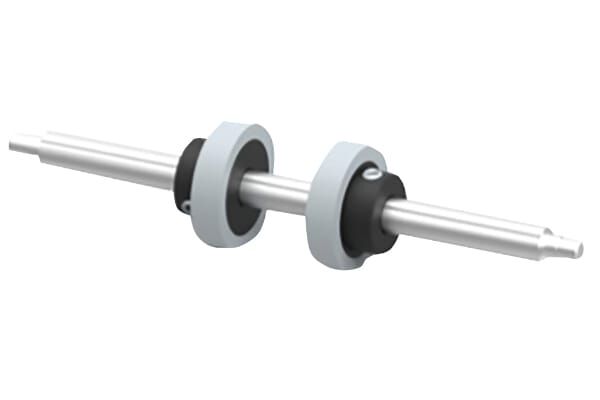

Roller Options

With the profiled, flat and precision roller options, a few moments' effort converts your WP2 from a flat-surface composite inspection tool, to a radial or axial pipe corrosion mapping system. Able to scan right to the edges of the part, convex, concave and even irregular surface area are catered for.

Perfect fit against OD and ID parts

All WP2 are designed to inspect flat surfaces as well as convex and concave curved surfaces. The curvature adjustment bar offers an intuitive graduated guideline that reads part radius of curvature (in both metric & imperial units).

Resources

Composite Inspection Benefits and Challenges Using Ultrasonic NDT Solutions

Ultrasonic Non-Destructive Testing (NDT) is widely used by engineers to inspect a range of composite materials including aluminium laminates and carbon fiber-based composites.

Sensitivity Response of Total Focusing Method (TFM) for Weld Inspection Versus Other Methods

Total Focusing Method (TFM) is an ultrasonic-based technique enhanced with the post-processing algorithm.

Advanced Corrosion Mapping

The WheelProbe 2 features a captive array in an adaptive rubber wheel making it a perfect corrosion mapping solution for large surface.

Inspection of Composite Structures

With advances in composite design and manufacturing to satisfy new applications, complex geometries are often required.

Accessories

Wheel Probe Options

WP2 64 Element

WP2 128 Element

| Description | WP2 64 Element | WP2 128 Element |

|---|---|---|

| WP2-5M128/64E-0.8x6.4 | WP2-0501 | WP2-0601 |

| WP2-10M128/64E-0.8x6.4 | WP2-0502 | WP2-0602 |

| WP2-2M128/64E-0.8X6.4 | WP2-0503 | WP2-0603 |

| WP2-3.5M128/64E-0.8X6.4 | WP2-0504 | WP2-0604 |

Storm Case

Included Accessories

| Description | Order No: |

|---|---|

| Spray Bottle | 195180 |

| Pump syringe nozzle | 152005 |

| Polyhib additive 125ml | |

| Storm case | WP3-ACC-0716 |

| USB Manual | 147417 |

| Maintenance tool | WP2-TOOL |

| MEK wipes pouch | WP2-ACC-0719 |

Handle Choices

(must choose 1 minimum)

Horizontal Handle

Vertical Handle

| Description | WP2 64 Element | WP2 128 Element | Both |

|---|---|---|---|

| Horizontal Handle | WP2-ACC-0501 | WP2-ACC-0601 | |

| Vertical Handle | WP2-ACC-0702 |

Roller Choices

(must choose 1 minimum)

Include Front Roller Bracket to use 2 rollers

Front Roller Bracket

Flat Roller

Profiled Roller

Precision Roller

| Description | WP2 64 Element | WP2 128 Element | Both |

|---|---|---|---|

| Roller Only - Profiled | WP2-ACC-0509 | ||

| Roller Only - Flat | WP2-ACC-0510 | WP2-ACC-0610 | |

| Roller Only - Precision | WP2-ACC-0511 | WP2-ACC-0611 | |

| Front Roller Bracket | WP2-ACC-0517 | WP2-ACC-0617 |

Cable Choices

(must choose 1 minimum)

| Description | WP2 64 Element | WP2 128 Element | Both |

|---|---|---|---|

| WP2-CABLE-veo-QX2.5 | WP2-CABLE-501 | WP2-CABLE-601 | |

| WP2-CABLE-SX-MX2-QX2.5 | WP2-CABLE-502 | WP2-CABLE-602 | |

| WP2-CABLE-MX-QX2.5 | WP2-CABLE-503 | WP2-CABLE-603 | |

| WP2-CABLE-veo-QX5 | WP2-CABLE-511 | WP2-CABLE-611 | |

| WP2-CABLE-SX-MX2-QX5 | WP2-CABLE-512 | WP2-CABLE-612 | |

| WP2-CABLE-MX-QX5 | WP2-CABLE-513 | WP2-CABLE-613 | |

| WP2-CABLE-CUSTOM | WP2-CABLE-151 |

Remote Control

Other Accessories

Laser Guidance Pack

Phone Display Holder

Demo Plate

Storm Case

| Description | WP2 64 Element | WP2 128 Element | Both |

|---|---|---|---|

| Laser Guidance Pack | WP2-ACC-0513 | WP2-ACC-0613 | |

| Remote Control | WP2-ACC-0712 | ||

| Phone Display Holder | WP2-ACC-0714 | ||

| Demo Plate for Wheelprobe 2 | WP2-ACC-0718 | ||

| WP2 Storm Case | WP2-ACC-0716 |