RSflite Composite Solution

Overview

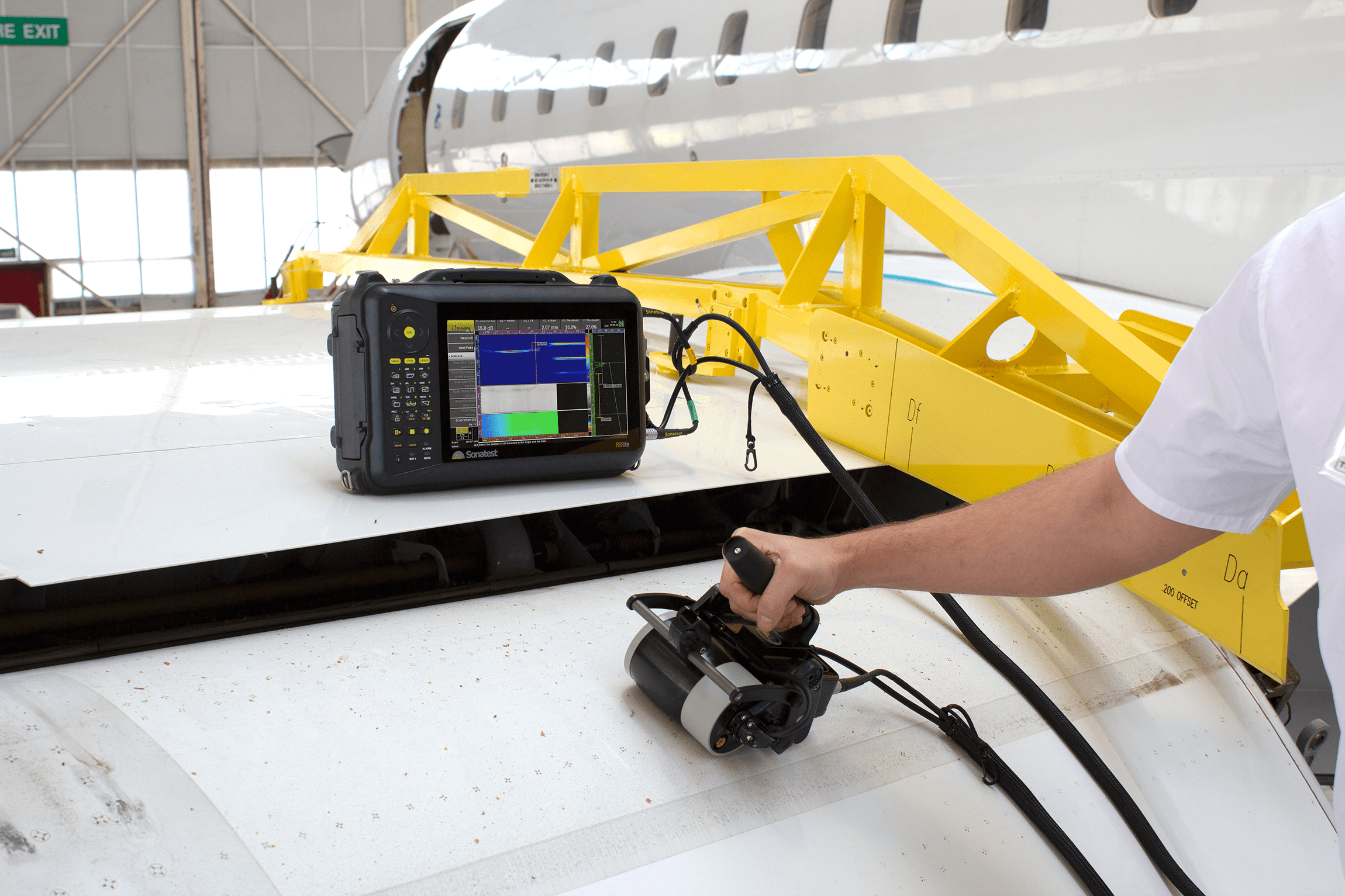

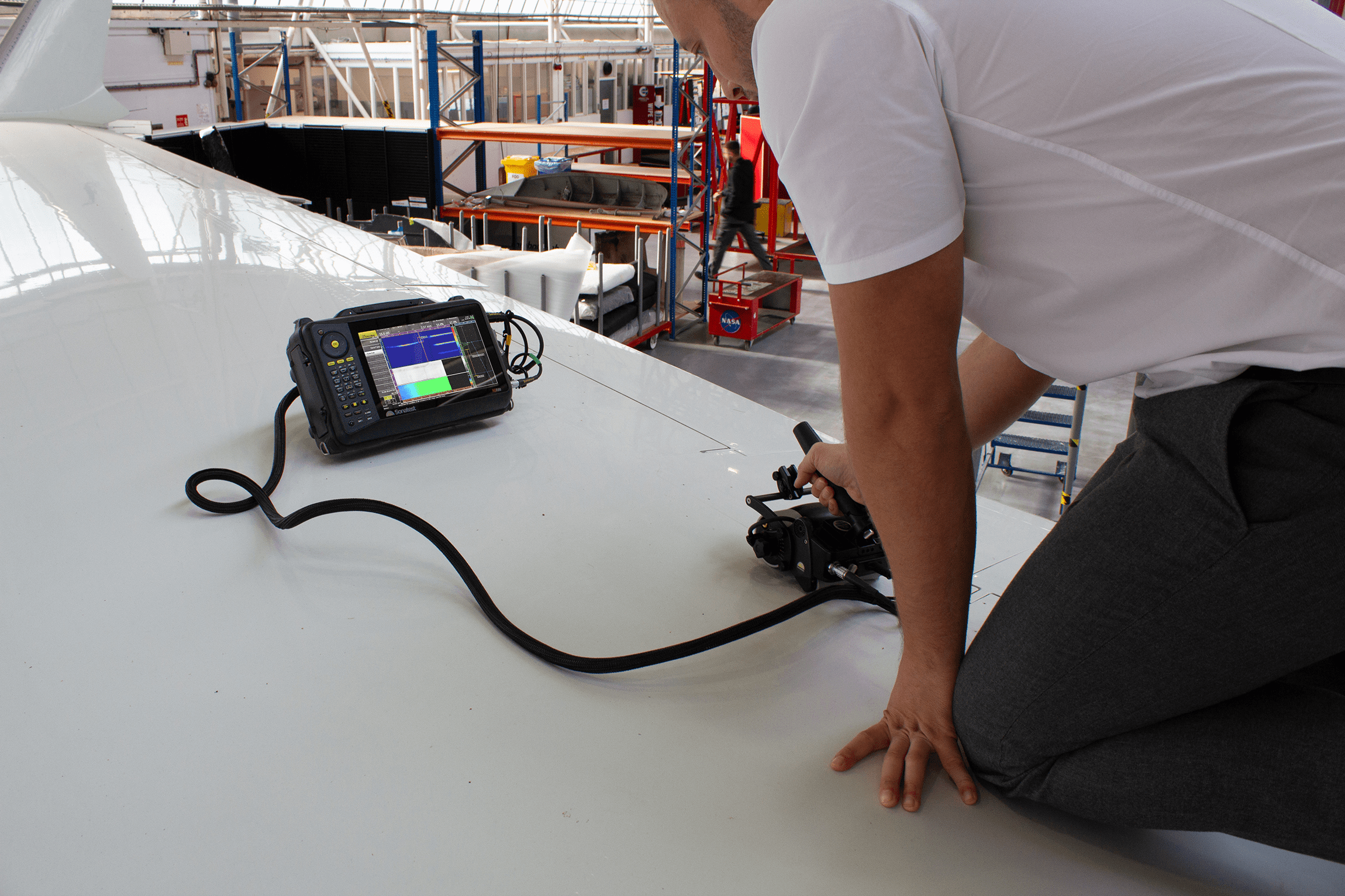

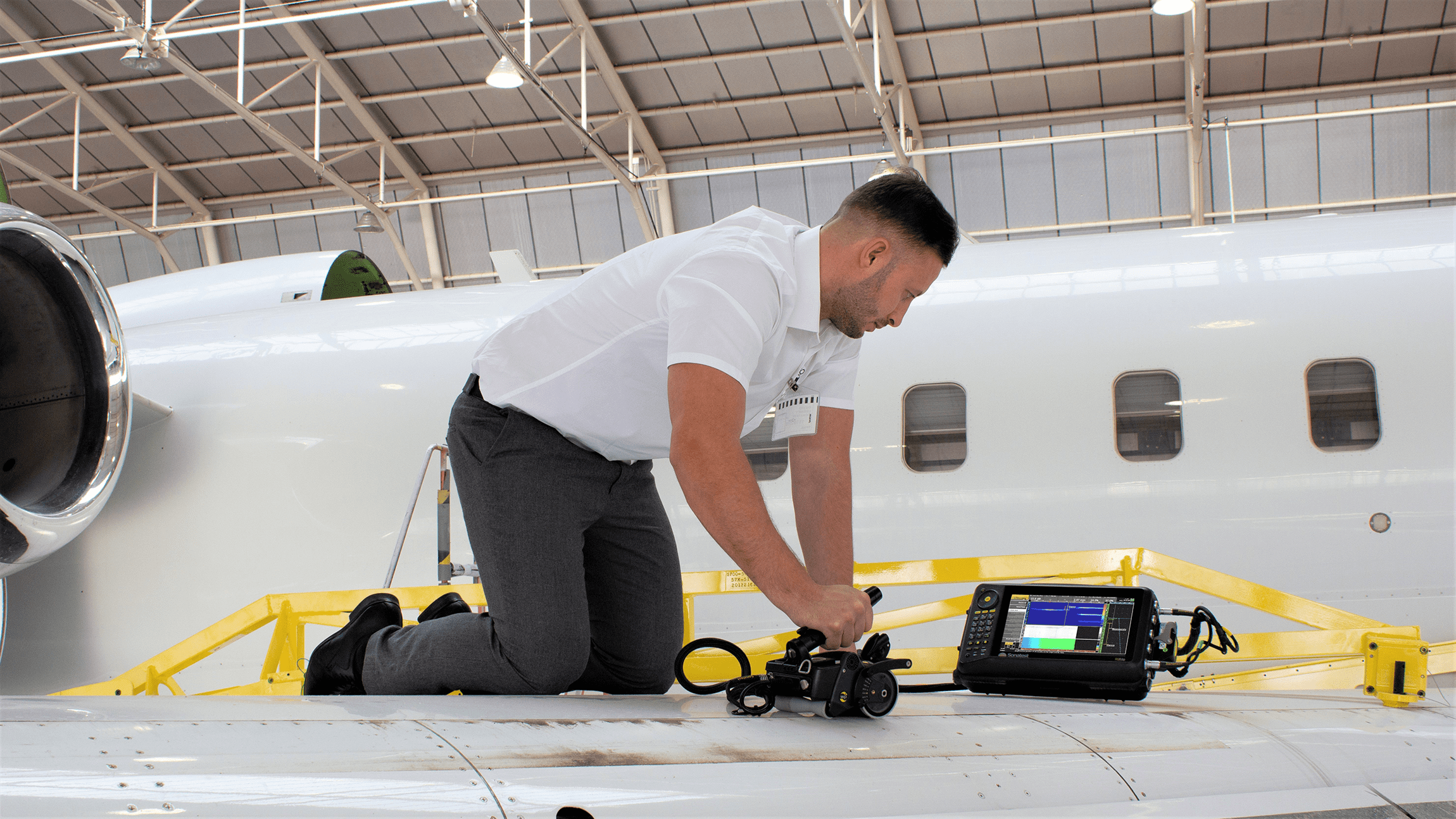

Fast, integrated and portable, this is an optimal inspection ultrasonic NDT solution for the composite industry.

Ultrasonic Non-Destructive Testing (NDT) has helped engineers inspect all sorts of composite materials for years. Whether it be traditional aluminium laminates or today's more complex carbon fibre-based composites, an ultrasonic NDT system has the ability to acoustically see through these parts and create complete inspection maps. Comprehensive volumetric integrity reports can be generated and supported by imaging reports that are as easy to interpret as traditional X-Ray.

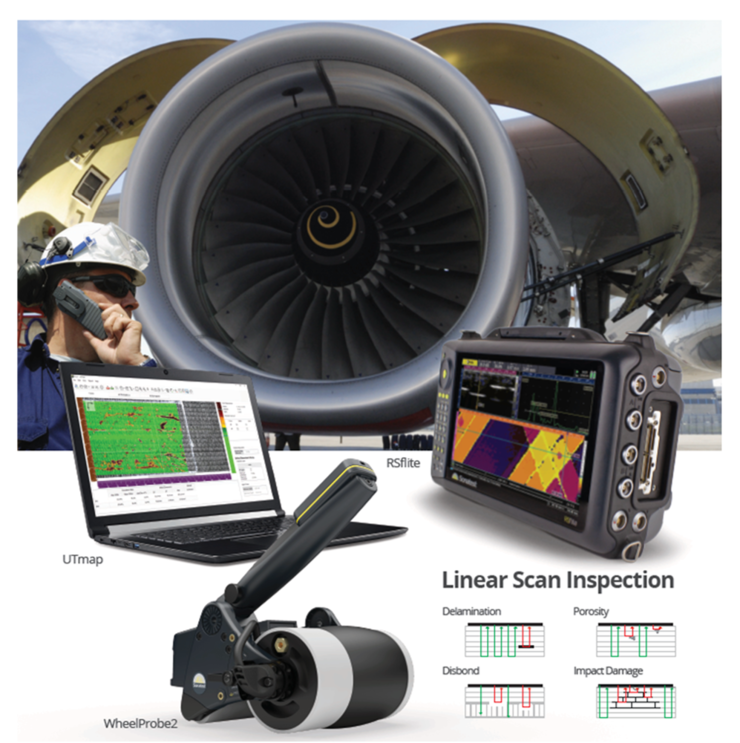

Active with key industry leaders for more than 60 years, Sonatest is proud to present the new generation RapidScan: the RSflite, UTmap and WheelProbe2 linear array solution.

Save time. Be more efficient

Fast composite inspection with

RSflite & WP2

Simplify your data

analysis with

UTmap

Enable automatic

measurements that are

ready to share

Features

Key features

- Light reinforced frame

- Patented rubber wheel

- Best acoustic's on the market

Advantages

- Portability with similar to immersion quality A-Scan data

- Ease of use with a lightweight and ergonomic design

- Up to 0.8 mm near surface resolution

Key features

- Linear Scanning

- Touch screen

- Portable device

Advantages

- User interface optimised for the composite inspection

- Fast setup and operations

- Outstanding inspection speed

- Ready for all site conditions

Key features

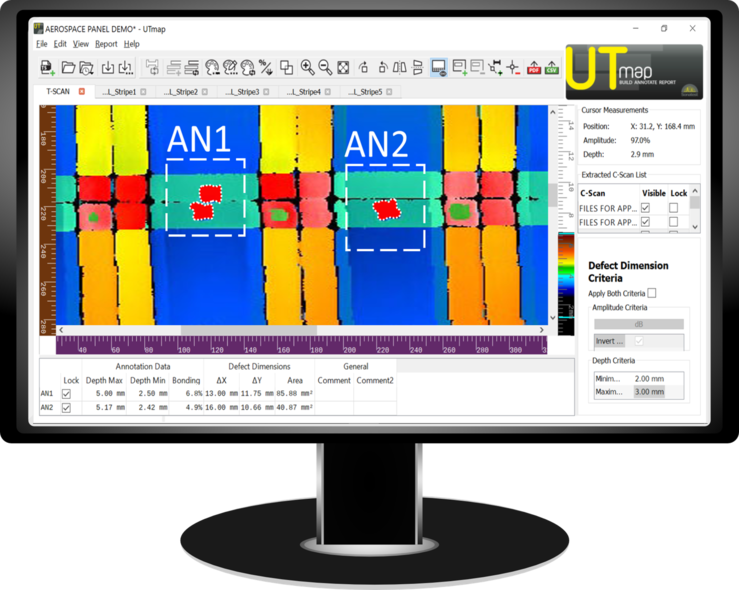

- T-Scan stitching

- Post analysis re-gating

- Automatic report

Advantages

- Data adjustments (gain, gates...) are easily done in post-acquisition

- Automatic measurements

- Fast data interpretation

- T-Scan, or the freedom to make it fit

Ultrasonic linear scanning solution

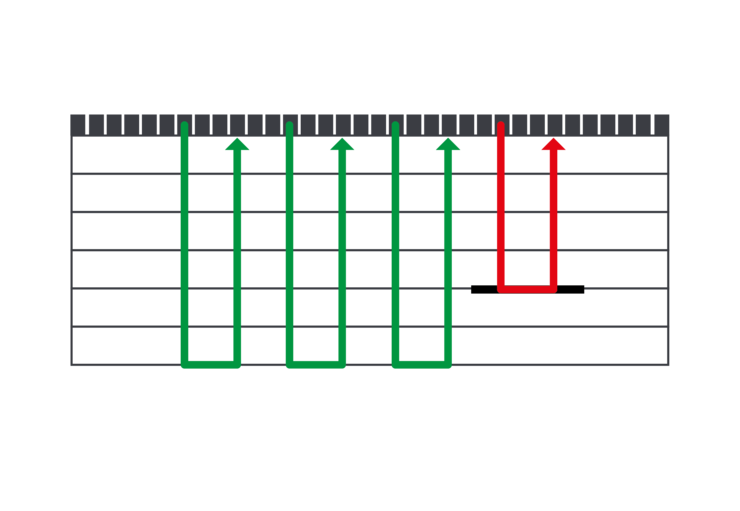

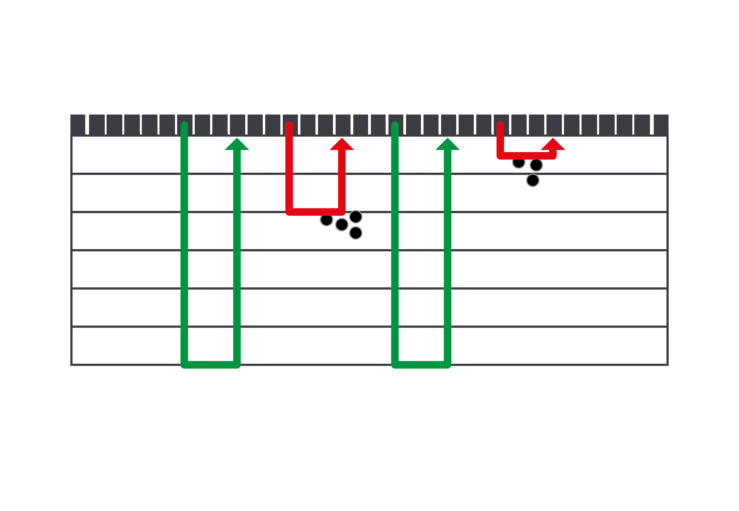

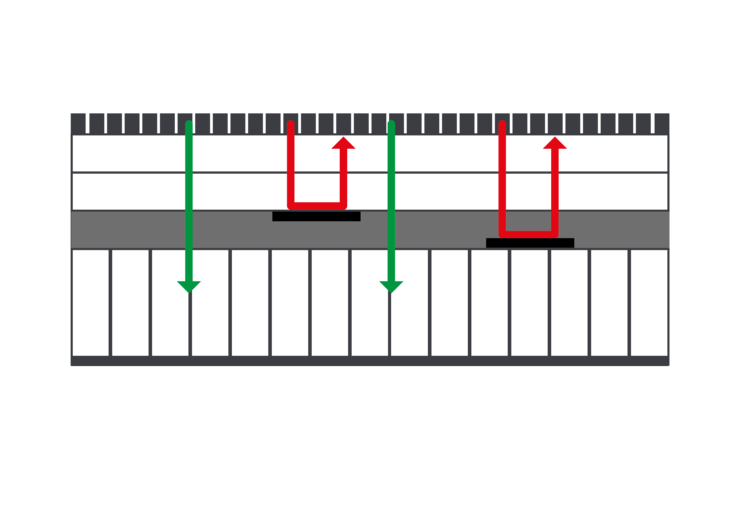

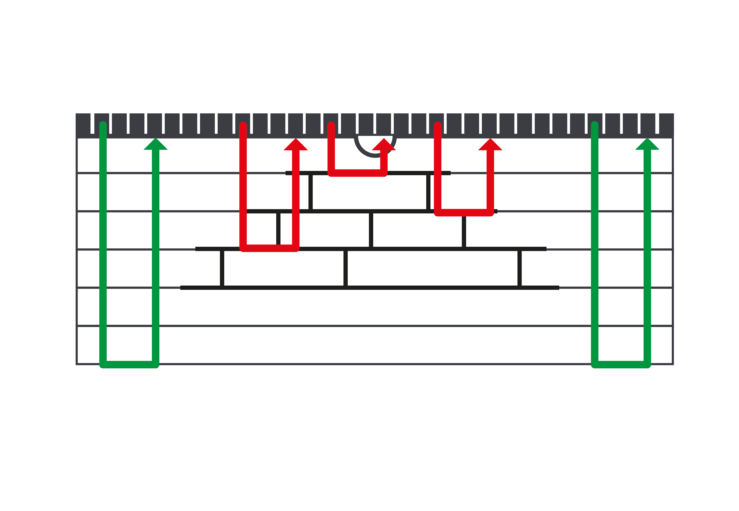

For composite inspection, a linear scan (L-Scan), sometimes referred to as an electronic scan (E-Scan), uses a group of elements of a linear array probe to pulse a single straight beam (1) , then another adjacent beam (2). This sequence is repeated equally over the full length of the array (3) .

This ultrasonic NDT technique is particularly efficient to detect the most common defects inside the composite structure as it covers large area's rapidly and generates high-resolution data sets and images.

Delamination

Delamination

Porosity

Disbond

Impact Damage

Advanced solution benefits

- With a linear scanning workflow-oriented and simplified user interface; the complete solution optimises the training time and on-site performances within one machine.

- The outstanding ultrasonic signal-to-noise ratio and patented WheelProbe2 rubber design is a system offering the best acoustic performances for composite inspection.

- The combination of RSflite and WheelProbe2 makes the fastest portable immersion inspection system on the market.

- The advanced UTmap analysis tools and unique C-Scan stitching capability increase overall productivity and enhance the inspection quality.

Resources

Composite Inspection Benefits and Challenges Using Ultrasonic NDT Solutions

Ultrasonic Non-Destructive Testing (NDT) is widely used by engineers to inspect a range of composite materials including aluminium laminates and carbon fiber-based composites.

Advanced Composite Inspection

A complete picture of a large component can be produced by stitching C-scans together in the UTmap software.

Sensitivity Response of Total Focusing Method (TFM) for Weld Inspection Versus Other Methods

Total Focusing Method (TFM) is an ultrasonic-based technique enhanced with the post-processing algorithm.

Linear Scanning with the Glider

The RSflite workflow is designed for composite inspections.

Roller Probe Inspection

The through transmission inspection technique is a widely accepted method for honeycomb assessments.

Low Frequency PA Inspection

The inspection of heavy composites thicker than 50 mm (2 inches) causes significant limitations for conventional phased array probes.

Low Frequency PAUT Inspection of GFRP

Certain heterogeneous materials can be highly attenuative to ultrasound. As a result, lower frequency probes are required, especially for thick sections which otherwise can be difficult to inspect.

Inspection of Composite Structures

With advances in composite design and manufacturing to satisfy new applications, complex geometries are often required.

Media

Gallery

Video

Portable Ultrasonic NDT composite Inspection Solution 5 min demo

Sonatest Pro Tutorial - Composite C-scan stitching with UTmap

Accessories

Standard RSflite Composite Solution Package

- RSflite instrument

- WheelProbe 2 - 5 MHz with 5 m cable

- WP2 Composite Pack

- WP2 advanced Kit 2 + Horizontal Handle

- UTmap License

- Xpair License

| Part Number | Part Description |

|---|---|

| RSFLITE BNC/LEMO | RSflite 128 channel linear scanning instrument |

| WP2-5MHZ-64E | WP2 5Mhz 64 Element Buggy |

| WP2-PACK2 | WP2 Composite Pack |

| WP2-CABLE-111 | WP2-CABLE-veo-QX5 |

| WP2-ACC-0501 | Horizontal Handle |

| WP2-ADV-KIT2 | Advanced Kit Two |

| UTMAP | UTMAP: single license |

| XPAIR | Xpair: single license |

RSflite Composite Solution Package with Glider Probe Option

- Standard RSflite Composite Solution Package

- Probe & Wedge

- Encoder

Standard RSflite Composite Solution Package plus

| Part Number | Part Description |

|---|---|

| X3A-003 | X3A-5M64E-0.6x10-SQX2.5 |

| X3AG-001 | X3AG-OLW25 |

| JX-1004 | Single Universal Encoder 2.5m |

RSflite Composite Solution Package with additional WheelProbe Buggy plus Test and Demonstration Plate Option.

- Standard RSflite Composite Package

- Extra WP2 probe (pick your frequency)

- Test and Demonstration Plate

Standard RSflite Composite Solution Package plus one extra WheelProbe 2 Buggy from the list below:

| Part Number | Part Description |

| WP2-2MHZ-64E | WP2 2 MHZ 64 Element Buggy |

| WP2-3.5MHZ-64E | WP2 3.5Mhz 64 Element Buggy |

| WP2-5MHZ-64E | WP2 5Mhz 64 Element Buggy |

| WP2-10MHZ-64E | WP2 10 Mhz 64 Element Buggy |

| Plus | |

| WP2-ACC-0518 | Demo Plate for WheelProbe 2 |

Downloads

| Date | Title | Version | Size | |

|---|---|---|---|---|

| October 2018 | RSflite Software Updates | Download | ||

| October 2018 | UTmap Analysis Software | Download | ||

| October 2018 | Xpair Remote Software | Download | ||

| 01.01.2014 | MSDS Panasonic Li ion Cell for 242171 | 132.72 KB | Download | |

| 01.01.2013 | Shipping & Handling Li ion Batteries | 361.36 KB | Download | |

| 07.05.2014 | Li ion Battery PSDS | 212.04 KB | Download |

| Date | Title | Version | Size | |

|---|---|---|---|---|

| Oct 2018 | RSFLITE-UTMAP-WP2 Composite Solution 5 min DEMO | Download | ||

| Oct 2018 | UTmap Stitching and C-Scan Mapping Solution | Download | ||

| May 2017 | Encoder Calibration | Download | ||

| May 2017 | Phased Array Automatic TCG Calibration | Download | ||

| May 2017 | Phased Array Element Activation Test | Download | ||

| May 2017 | Phaased Array Sensitivity & ACG Calibration | Download | ||

| May 2017 | Phased Array Velocity & Zero Calibration | Download | ||

| May 2017 | Phased Array Wedge Angle Calibration | Download | ||

| May 2017 | Phased Array Wedge Delay Calibration | Download | ||

| May 2017 | Remote Control Connection | Download |