Echo to Echo and Coating Thickness Measurements

Many applications in the Corrosion thickness applications have painted surfaces on vessels, ship hulls, pipes, bridges, and tanks.

This application note is about whether Echo-To-Echo has the ability to either ignore the paint/coating and measure just the substrate or measure both coating and substrate at their independent velocities.

In the past, the customer would spend the time and money to remove the coating knowing the thickness of the coating has nothing to do with the integrity of the substrate but ever more, the coating thickness introduces an error. In addition, the part then needs to be re-painted. When using a conventional gage without echo to echo (ignoring the coating), the error is simple to calculate. The thickness on conventional gages is based on one sound velocity, that typically of steel.

Since coatings have roughly 2.5 times slower sound speeds than steel, a .010” coating would automatically introduce an error of .025’ (.010” x 2.5). ECHO To ECHO measures the sound bouncing in the steel only thus ignoring the coating. We now also have the ability to measure the coating and the substrate at their independent velocities with the Alphagage+ CW or Alphagage+ CDLW. The use of the live waveform is recommended to look for mode converted echoes (Longitudinal waves becoming shear waves) as well as the ability to adjust gain and blanks…both main bang blank and blank after first detected echo.

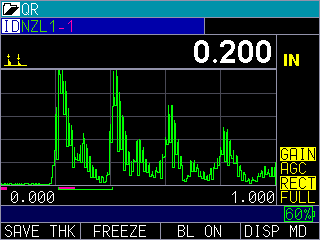

ECHO To ECHO on, see top left yellow peak symbol, also main bang and blank after first detected are on, see fushia colored lines on the bottom of the screen.

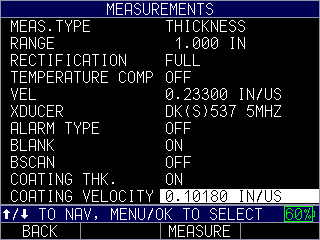

Turning on coating in ECHO unit, generic velocity is set.

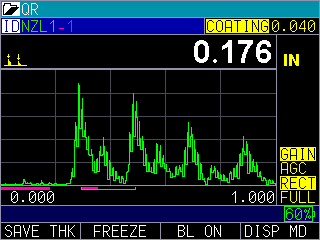

After a two-point substrate thickness and coating velocity cal, we display both substrate and coating thickness.