Wave Nozzle Inspection

In an A-Scan only view, signals can be difficult to interpret. Small inaccuracies in probe positioning or the angle of reflection may place a signal as a defect in the weld when in fact it is a reflection from the internal wall.

Nozzles and Nodes require a high skill level to inspect, varying geometries, differing thicknesses and tight angles all combine to create a challenge for inspection and interpretation.

In an A-Scan only view, signals can be difficult to interpret. Small inaccuracies in probe positioning or the angle of reflection may place a signal as a defect in the weld when in fact it is a reflection from the internal wall. Situations like this can lead to false calls and unnecessary repairs.

By utilizing the WAVE's unique scan plan and live ray tracing ability, the inspector is able to see exactly where a signal is positioned and give the inspector greater confidence in their result. The ability to screenshot the scan plan also enabled more detailed reporting, giving clear and precise images of where any defect indication is positioned within the weld area.

|

|

|

|

|

|

|

|

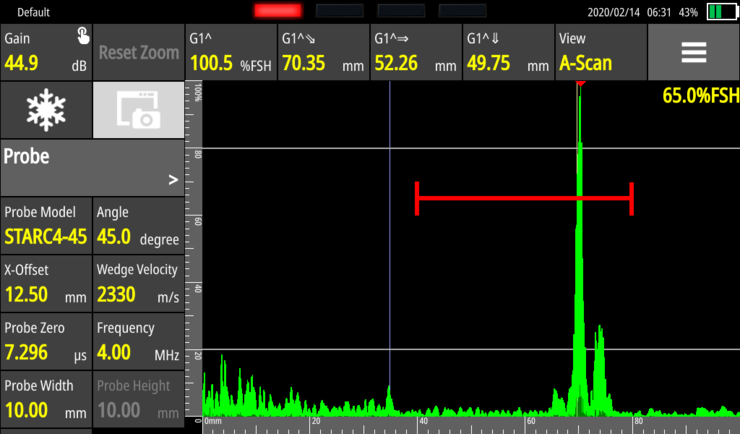

Images above show a toe crack indication on the A-scan and Scan plan ray tracer.

|

|

|

|

Images above show a lack of sidewall fusion indication on the A-scan and Scan plan ray tracer

Inspection Procedure:

The tests shown in the data images were performed on two different samples, one being a pipe to pipe node, and the other a pipe to pipe nozzle with a 120 degree angle. The wall thickness of the pipes varied between 15mm and 25mm.

The probes used in this inspection were 4MHz, 45, 60 and 70 degree Sonatest Starc shearwave transducers. The transducers were positioned on both the main pipe and the nozzle/node itself depending on the area of the weld in which we were trying to detect a defect.

|

|

|

|

Practical Outlines:

Need for inspection:

Nozzle / Node welds can be put under large stresses depending on the service the pipeline is under, internal pressure, cyclic loading, temperature differences and weather induced issues are common.

During the welding process, defects can be introduced such as slag and porosity. Over time and as a result of stress these defects can grow, or cracks can begin to form in certain high-risk areas around the weld.

In order to be certain that these welds are suitable for operation, vigorous NDT needs to take place and with the new Sonatest WAVE a technician’s confidence in correctly calling defects is increased.

Benefits of inspection using the WAVE:

The Sonatest WAVE has live ray tracing capabilities, this means the operator can draw a scan plan of the part and then adjust the probe offset. When an indication appears on the A-Scan, the technician changes to the ray tracer view with one touch, moves the probe to the correct offset and then the unit will show them where the reflection is coming from.

The Sonatest WAVE is also a very fast and user-friendly instrument, as well as the ray tracer, it is possible to create unique applications to suit specific inspections, removing menus or creating bespoke menus with only the necessary parameters in them.

While the inspection is underway, screenshots can be easily taken by one touch, making reporting much easier. These images can be quickly downloaded using Sonatest “companion” software and then placed into reports so that the customer has a clear visual identification of where a defect is positioned within the weld.

The Sonatest WAVE gives greater confidence for inspectors and clients by giving clear and precise images of where a defect is located or even identifying if a reflection is from a defect, geometry or mode conversion.

PAUT can also be used for this inspection, often though a special scanner is required which adds to the cost of a PAUT set and transducer. Awkward geometry can also cause multiple reflections when using this method, causing more potential confusion. With the WAVE simple but effective ray tracer, all reflections can be easily identified as either a defect, geometry and mode conversion.

For further information or support, please contact the Sonatest Applications Team: applications@sonatest.com.