Spot-Weld Ultrasonic Inspection

Sonatest rubber tips are designed to be used with the RDT delay line family and offer an effective alternative to the more traditional approach of water filled contact probes.

Spot-welds on automotive components and other structures require inspection for a number of possible failure modes including adhesive (stick) welds, burnt welds and non-fused welds.

Sonatest rubber tips are designed to be used with the RDT delay line family and offer an effective alternative to the more traditional approach of water filled contact probes. They have better life expectancy than water filled tips and the use of rubber dramatically reduces the amount of couplant required to ensure good contact. The flexible surface works exceptionally well on uneven surfaces.

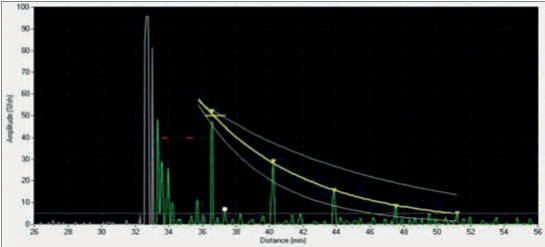

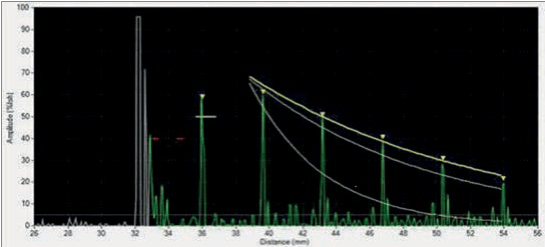

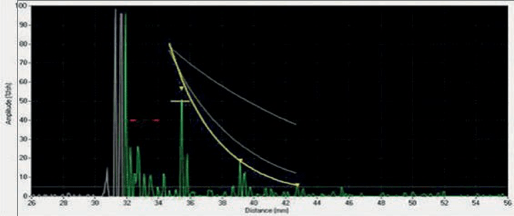

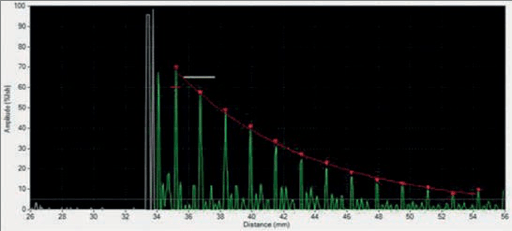

Using the pulse echo technique, the following results may be seen:

|

|

|

|

|

|

|

|

Conclusion

Manual testing can be very effective in detecting ‘defective’ weld conditions associated with spot weld joining process. This is always operator dependant and needs a good basic understanding of ultrasonic principles. The main benefit of manual testing is primarily the low cost and portability when compared to larger fixed or robotic systems.

For further information or support, please contact the Sonatest Applications Team: applications@sonatest.com