Optimal Workflow for Composite

5th February 2020

5th February 2020

Harry Britten

Technical Support, Sonatest

Performant solutions come with mainstreamed processes. Here is a good one for composite quality control!

Linear scanning is the appropriate Non-Destructive Testing (NDT) method for inspecting composite materials. A robust plan limits errors and confirms quality monitoring.

Among the main benefits of developing and following a good workflow, there is a more efficient process that saves time and a sequential order that minimise the potential errors of manipulation at different stages.

For ultrasonic linear scanning evaluation, a good workflow includes 3 simple steps:

- Scan

- Record

- Report

1. Scan the part

The scan step refers to the acoustic parameters that have to be considered for the composite material. For ultrasonic NDT, the A-Scan is the basis of the acquisition and data set. The quality of it means everything as the data crossing the gate in the A-scan is directly used to generate the 2D C-scan inspection mapping. Quality comes from the linear array probe itself and the recording system (next section).

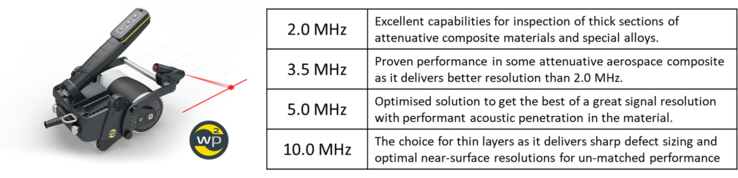

For a good scan, the linear array probe delay line and frequency have to match the composite material thickness requirements and acoustic properties. On the other hand, innovative design can help to speed-up the scan process. As an example, the Sonatest WheelProbe2 integrates all in one:

- the linear array probe;

- the delay line (water column);

- the coupling layer (patented rubber tire);

- the encoder.

This handful solution delivers similar performances as an immersion system - but portable! - and can rapidly scan large surfaces evenly and efficiently.

During the scan, another advantageous practice is to include an overlap between C-scan strips to forgive alignment errors. Indeed, these can be overcome during the reporting process (last section) by precisely adjusting the position of each strip. However, this can also be minimised using laser guidance directly mounted on the probe; this is especially useful when scanning large part like an aircraft fuselage for instance.

2. Record the information

When recording inspection data, the acquisition instrument quality has to meet the material properties, and its user interface must be optimised to the needs of the technician. In the composite industry, the ultrasonic linear scanning technology is key. A device that is purely designed to manage L-scan, like the Sonatest RSflite, combines both performances of the solution with the simplicity of operation. Moreover, the training time and cost can be reduced as most of the Phased Array concepts (like beam steering) are not applicable to L-scan, which also greatly facilitates the calibration process.

3. Report

At a glance, a report sums up the inspection made. It must be clear, concise and visual. For ultrasonic NDT of composite materials, the C-scan mapping is the best way to meet these requirements. The objective in the C-scan analysis step is to assemble the scan stripes from different sections and create a meaningful image for analysis and reporting.

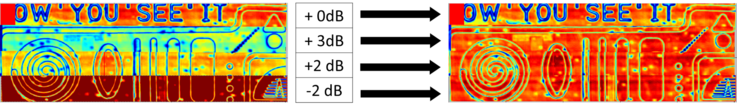

When reviewing a C-scan mapping, some strips of data may need to be precisely re-gated, boosted (add some gain) or re-aligned to match the part geometry. Taking into account the number of strips a large part can generate, software solution like the Sonatest UTmap helps the user to facilitate this last but important reporting step. Other features like automatic defect measurement tools also help to improve defect sizing precision in a reliable and repeatability manner.

In conclusion, the combination of the three steps detailed above reduces the entire inspection process from acquisition to submit a final report. An optimised workflow also opens the doors for improved quality and production throughput.

Useful references:

- Learn more on how to analyse ultrasonic NDT C-Scan mapping

- Learn more about the concept of ultrasonic NDT Linear Scanning

- Learn more about RSflite and UTmap composite solution

- Learn more about the WheelProbe2 scanning solution