Keep up with the increasing demands of the NDT industry

27th May 2020

27th May 2020

Harry Britten

Technical Support, Sonatest

With ageing infrastructure worldwide and Government emphasis on public safety regulations, the NDT industry is expected to grow by approximately 7% by 2024.

One of the main challenges of service providers is finding a realistic solution for the increase in demand for inspections.

The importance of retaining current skills

Since certified ultrasonic technicians are in high demand due to the certification requirements, service providers are forced to explore different approaches to retain their existing workforce and should be looking to invest in qualifying new operators as their business expands.

One of the biggest challenges for senior NDT engineers is maintaining compliance within the standards and procedures whilst organically growing their business. Besides identifying ideal candidates to carry out inspections, providing advanced and comprehensive training for new operators can be time-consuming and expensive. This is why many NDT organisations are now looking to adopt smarter, interactive NDT equipment for their application requirements.

Advanced ultrasonic equipment, designed to meet the growing demand

The new generation of ultrasonic instruments is advancing into the age of smart platforms. However, it’s not uncommon for an operator to adopt a particular brand and consequently show a considerable level of hesitance towards newer technologies, regardless of the benefits. Getting trained with new ultrasonic equipment can be a costly and time-consuming exercise for both experienced and new ultrasonic technicians. However, if technology can help to lower training costs, this would benefit service providers in their short and long-term commitments to public safety.

How the WAVE helps with efficient, hands-on training

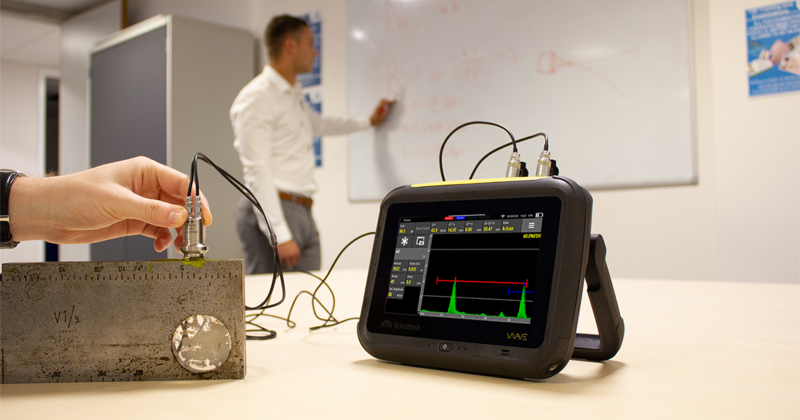

Sonatest WAVE is the first smart flaw detector with an integrated interactive scan plan that allows the visualisation of the beam reflection in real-time. Knowing that 65% of people are visual learners, this instrument is sure to speed up the training process and reflect positively on the costs.

Click here for more information

Utilising WAVE companion software, NDT managers can customise the user interface with all the parameters relevant for the inspection, meaning a more user-friendly interface with just the parameters required. Since all parameters are set in advance, managers can provide more customised training in a shorter period of time. Even if the operator is not familiar with the new equipment, they will be guided directly through the functions.

By providing customised training for application-specific tasks, you can expect an overall reduction on the time dedicated to the actual training. Therefore, service providers will be able to continuously keep up with the increasing demands of the NDT industry.