Decrease the risk of human error in inspection using the Sonatest WAVE

![]() 1st July 2020

1st July 2020

Marie-Pierre Despaux

Sonatest

According to the Federal Aviation Administration (FAA) of United States “as many as three out of four aviation incidents result from some kind of human error”.

Therefore, human factors should be considered an intrinsic component of the inspector’s role. Being an inspector can be challenging with both physical and mental stress. In shutdown periods, the window of opportunity for inspection is short and with restricted schedules, along with the associated costs, the pressure is high.

The challenges of technicians

Operators face many challenges, such as a non-intuitive instrument while inspecting a complex part in a narrow, noisy, and poorly lit environment. Unfortunately, most operators have experienced such a scenario. These factors cannot be ignored when it comes to the qualifications of the inspector, test procedures and, of course, the equipment.

The test environment and conditions are not always ideal. For example, operators’ working positions and harsh environmental temperatures can make it difficult for a technician to proceed with inspection. Therefore, the inspector may doubt their capabilities under these circumstances.

Increase confidence with the WAVE solution

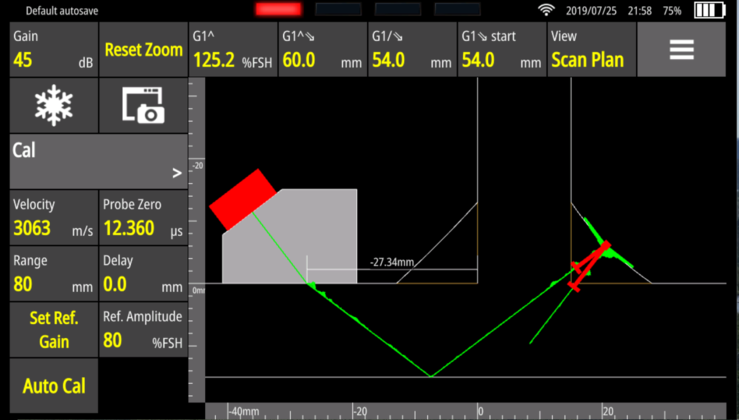

The WAVE was developed to simplify the operator’s workflow whilst increasing the confidence level e.g. utilising the interactive scan plan and ability to customise the applications. An interactive scan plan allows the user to see the sound path and the skips, even through weld caps and complex geometries such as a T-joint or corner joint.

An accurate visualisation increases the technician’s confidence level as they can expect a more reliable data output, this ensures an adequate probability of detection and reduces the risk of making false calls. Nevertheless, operators’ uncertainties remain an important element that can negatively influence the probability of detection of defects.

Wave Interactive Scan Plan