How the Sonatest WAVE Adapts to the Challenges of Civil Aviation

![]() 30th March 2020

30th March 2020

Philippe Rioux

Sonatest

Have you ever had to re-do a group of inspections, because one critical parameter was different than that dictated by the procedure?

Well, this is no longer a problem with the new Sonatest WAVE solution!

As dictated by the International Civil Aviation Authority, for each in-service cycle of the aircraft, overall inspection and maintenance is required. Inevitably during this period, the aircraft is not generating any revenue, resulting in significant financial losses. Nevertheless, missing a crack on a critical component during a routine inspection is certainly not an option. Aerospace NDT service providers are always on the lookout for tools to help improve their inspection efficiency, without compromising the inspection integrity. New advanced technologies and additional diagnostic software may significantly improve the inspection conformity and reliability.

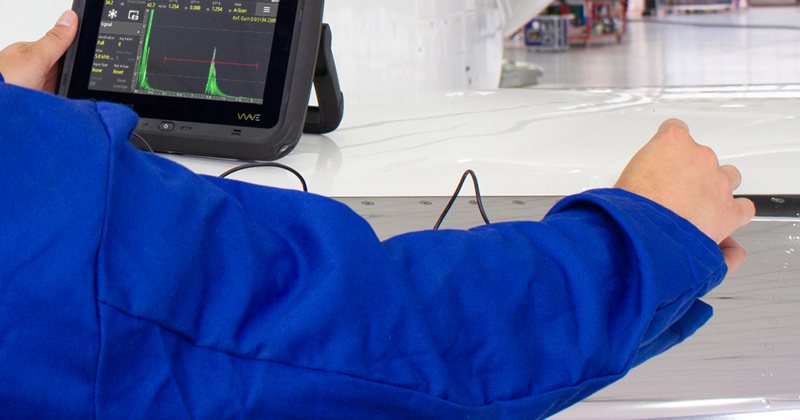

Using the WAVE for Inspections in Civil Aviation

Sonatest WAVE combines conformity and reliability by utilising a customised user interface. Additionally, the WAVE companion software provides all the necessary tools to the NDT manager in order to create application-based inspection procedures, where only the mandatory parameters are visible in the user interface. Hidden/locked parameters are defined ahead of the inspection, minimising the risk of human error and maximising the overall efficiency. Moreover, the user interface can be rearranged into a dedicated menu to streamline operator’s workflow and help mitigate human errors.

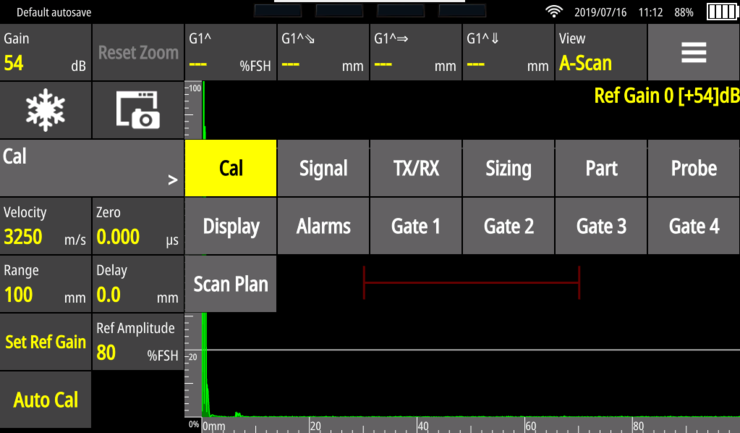

In the example below, all the parameters are set in the WAVE companion software prior to inspection. Some hidden functions are not accessible for the field operator and some are in read-only mode to help validate the inspection setup. In the menu a reference A-Scan of the calibration block could be saved and kept in the background at all times.

Figure 1 - Enhanced WAVE application based on a specific manufacturing procedure

(Bombardier deHAVILLAND DASH8 series 300)

Why the WAVE Works

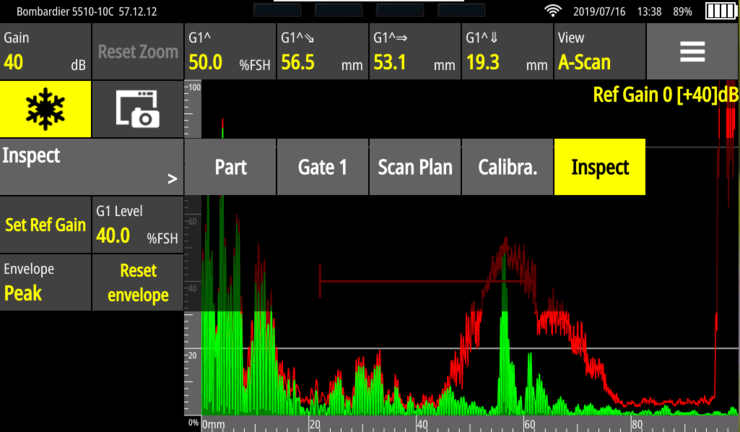

At Sonatest we think slightly differently, and we believe we’ve created a unique user experience for ultrasonic testing with the WAVE Application Concept. Having the ability to modify all the necessary requirements at your fingertips is exactly the key to a quick and easy inspection process. Our emphasis on a lean design philosophy means less training requirements and long-term financial benefits. The intuitive user interface, with an easy to use display, will guarantee workflow optimisation as well as preventing potential operational errors. Nevertheless, any savings on the inspection time will reflect positively on the workmanship.

Click here for more information

Figure 2 - Optimised menu during inspection